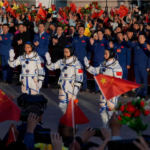

For almost ten years, Apple has been looking for ways to reduce its heavy reliance on China for iPhone production. Now, with the launch of the iPhone 17, the company is making its boldest move yet. According to Bloomberg, all four iPhone 17 models — including the premium Pro versions — will be manufactured in India ahead of their global release.

This marks the first time Apple will produce its entire new iPhone lineup outside China from day one. Industry experts say the decision is more than just a supply chain shift; it’s a strategic transformation with global implications.

Why Apple Is Moving Away From China

Apple’s relationship with Chinese factories has long been both an advantage and a liability. Manufacturing in China kept costs low and ensured massive production scale, but it also left Apple vulnerable to:

- Geopolitical tensions between the U.S. and China

- Tariffs and trade wars

- Supply chain disruptions

- Intellectual property concerns

“Apple’s move shows that resilience is now as important as efficiency,” explained Mark N. Vena, president of SmartTech Research. By building in India and diversifying into countries like Vietnam, Apple is rebalancing its global strategy.

Stephen Ezell of the ITIF added, “Apple has proven that countries like India can now produce complex consumer electronics at a scale once thought possible only in China.”

A UBS study backs this up, revealing that 71% of U.S. companies operating in China are already shifting or planning to shift manufacturing elsewhere. Rising costs and ongoing business risks are driving the exodus.

The Risks of Leaving China

Not everyone sees this move as risk-free. Rob Enderle of the Enderle Group argued that Apple’s strong margins have long depended on China’s efficiency and quality. Training new Indian assembly lines could initially cause quality hiccups.

Still, Apple is investing heavily in worker training and oversight to ensure its brand reputation isn’t compromised. “Consumers won’t notice a difference,” Vena assured. “Apple is making sure ‘Made in India’ means the same reliability as ‘Made in China.’”

Apple’s Tariff Strategy and India Expansion

Apple began manufacturing in India in 2017 with the iPhone SE and has steadily expanded production. The iPhone 17 will be assembled across five Indian factories, cementing India’s role as Apple’s second major manufacturing hub.

Tariffs are also a key driver. India imposes steep tariffs on imported electronics, which initially motivated Apple to produce locally to avoid higher costs. Meanwhile, U.S. tariffs on goods from China and India have added further pressure. Apple managed to sidestep these costs by committing $600 billion in U.S. manufacturing and semiconductor investments.

Morningstar analyst William Kerwin estimates that tariffs could cut Apple’s earnings by as much as 15% if exemptions end. So far, iPhones have avoided these tariffs, but diversifying production helps protect Apple’s margins.

India as Apple’s Future Growth Engine

Industry analysts agree that Apple’s strategy isn’t just about avoiding risks — it’s about long-term growth. India is not only a cheaper production hub but also a massive emerging market with over a billion consumers.

“Apple is embedding itself into India’s economy,” said Vena. “This isn’t just about manufacturing; it’s about positioning the iPhone for explosive sales growth in a country where smartphone adoption is still climbing.”

Tim Bajarin of Creative Strategies added that political risks will always exist for global companies, but Apple is playing smart by diversifying and aligning production with demand.

The Bottom Line

Apple’s decision to make the iPhone 17 entirely in India is one of the company’s most important strategic moves in years. It reduces dependency on China, protects against tariffs and geopolitical risks, and positions India as both a manufacturing hub and a key market for future growth.

In many ways, this move could shape Apple’s next decade of success — just as the iPhone defined its last.